Ford will deepen its European path toward a carbon-neutral footprint by 2035, announcing agreements with major suppliers to assure steel supply from a low-carbon technique.

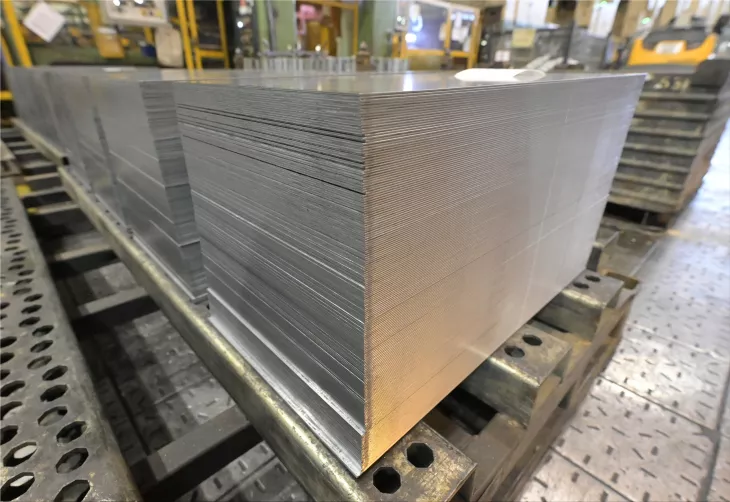

Ford took additional initiatives today to assure the supply of low-carbon steel in Europe for future products and contribute to the company's aim of achieving a carbon-neutral footprint by 2035. Ford has signed agreements with Salzgitter Flachstahl GmbH, Tata Steel Nederland BV, and ThyssenKrupp Steel Europe AG to ensure its supply of low-carbon steel.

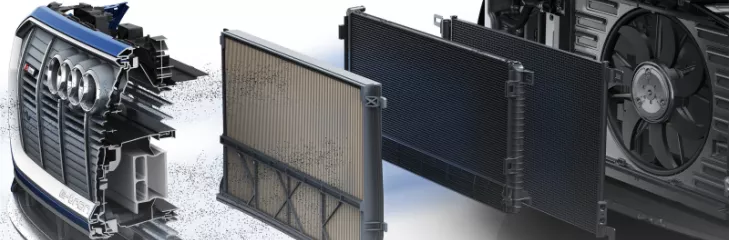

Ford's three strategic suppliers each have plans to enhance low-carbon steel output in the coming years. Ford will dramatically reduce the CO2 footprint of its supply chain, with steel manufacturing playing a crucial role, thanks to solid ties with these partners. Ford intends to employ low-CO2 steel in manufacturing its new Ford Mustang Mach-E electric crossover beginning in 2023.

Reducing CO2 emissions from the supply chain is a critical component of Ford's ambition to have a carbon-neutral European footprint by 2035 across plants, logistics, and suppliers. Ford is looking at the whole value chain to manufacture efficient vehicles to meet this lofty target. Significant modifications are going place at the Electrification Center in Cologne, with new energy-efficient solutions that will lower emissions by more than 2,000 tons of CO2 and consumption by more than 2,600 MWh of power each year.

Steel producers will gradually lower their CO2 footprint in steel manufacturing by incorporating green hydrogen and renewable energy into new production processes. They will therefore contribute to the European Green Deal's goal of reaching net zero emissions in all sectors by 2050.

"Our consumers, like us, want to take care of our world," said Sue Slaughter, Director of Procurement and Supply Chain Sustainability. "Improving our supply chain is critical, and by using carbon-neutral steel, we will take a significant step toward decreasing our cars' CO2 impact."